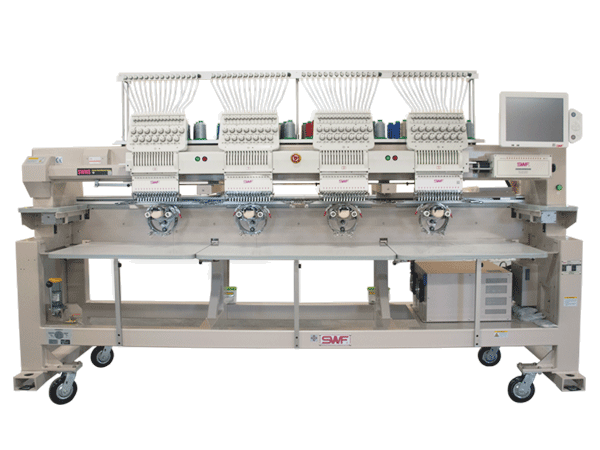

The Smartest, Fastest Automatic multi-head embroidery machine ever created

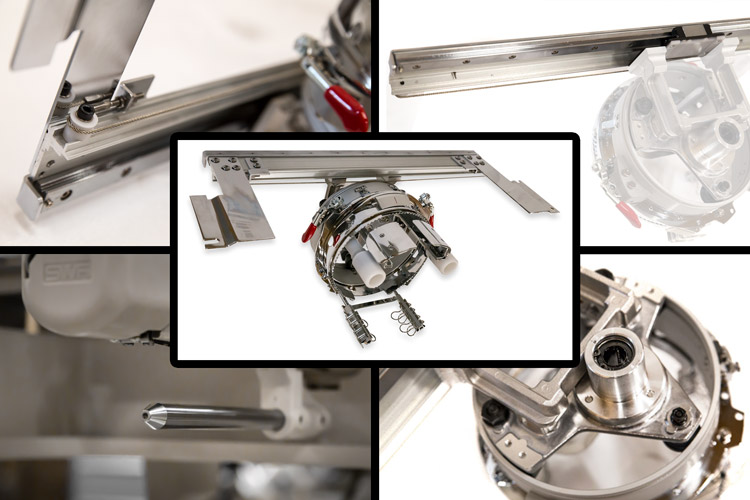

An independent presser foot motor is behind the automatic adjustment of the presser foot height. This ensures great quality embroidery, regardless of the fabric thickness.

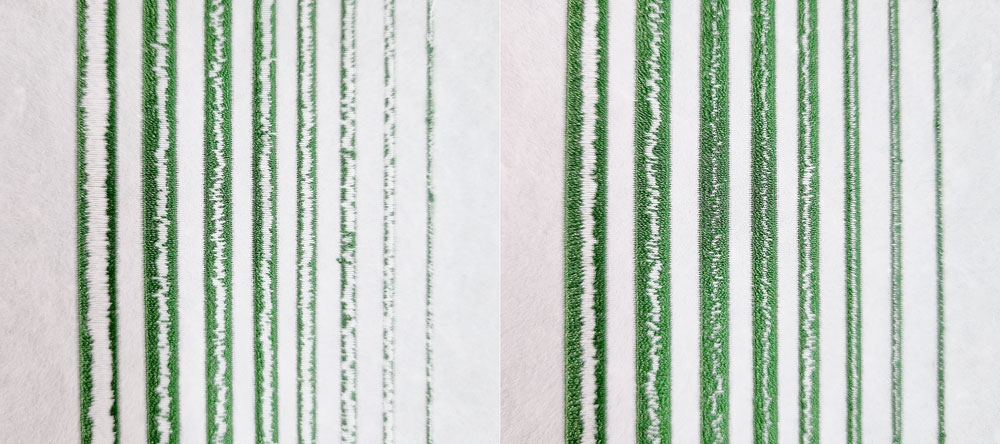

Smart Tension System automatically adjusts the thread tension by analyzing the stitch type and machine speed.

Produce consistently high-quality embroidery with STS and reduce lost productivity in manual adjustment of thread tensions.

The SWF KX Series has a redesigned slim cylinder arm to improve the quality of embroidery detail onto smaller products, including sleeves, cuffs, collars, infant wear and more!

Traditionally, switching between flat work and cap / hat work is quite time-consuming and fiddly, requiring tools and removal / application of screws and fasteners. The SWF quick change cap system has changed all that. Easily switch between caps and flats and back again in a matter of seconds without tools and without the risk of losing fasteners and screws!

See a video demonstration at: https://youtu.be/xC__kB39ygc

All SWF tubular embroidery machines also come standard with two sets (per head) of 9, 12, 15 and 18cm round hoops, 30x30cm rectangular hoops, large rectangular hoop (size dependent on machine model), and cap frames.

Add the patented Quick Change Cap Frames to further increase your productivity

Increased Running Speed

Up to 1200 spm – and 1000spm on caps!

Servo Motors

Servo motors increase stitch quality, registration accuracy and reduce overall operation noise.

Wi-fi connectivity

Wi-fi & Ethernet LAN enabled

Barcode Scanner Connection

Make sure the right design is loaded and stitched

Expanded Memory Size

Memory capacity stores up to 40,000,000 stitches!

Save colour sequences

New machine file format allows you to save colour / needle sequence with the design

Repetition Work

Perfect for embroidered badges or patches or motif work, one design can be repeated up to 99 times along X or Y or XandY directions, or several designs can be repeated together up to 63 times

Manual Offset

Manual Offset allows the user to manually move the frame to a pre-selected point. This feature makes it easy to do appliqué or to change frames while embroidering

Float Stitch Function

The frame and the needle bar can move back and forth by increments of 1, 100, 1,000 and 10,000 stitches, and by colour, without stitching

USB Ports

The USB ports allow you to easily move designs to and from your embroidery machine using USB external storage devices

User Friendly LCD Screen

15.1 inch colour LCD screen displays set and current speed, shows real time embroidery status and error indicators if the machine has stopped unexpectedly

Mirror Image and Design Direction

Designs can be rotated from 0° to 359° in 1° increments. Designs can also be flipped horizontally.

Thread Break Sensor

The machine will detect when the upper or lower threads break or run out, and will automatically stop

Editing

The edit function allows users to delete, modify, and / or insert stitch data and function codes such as jump stitch, end, and trims.

Frame Reversal

When thread breaks or runs out, you can move the needle bar back to the break point (or even to the start of the design) in increments of 1 to 10 stitches

Reduce and Enlarge Designs

Selected designs can be enlarged or reduced from 50% to 200% by 1% increments and in any direction

Automatic Offset

The frame automatically returns to the offset point when the embroidery is finished to make it easier for you to switch the frames. you can select AUTOMATIC OFFSET at PARAMETER SELECT MODE to move the frame automatically to the desired point, making it easier to do appliqués and emblems

Origin Return

The frame can be returned to origin point of design during embroidery work

Automatic Return

The frame will move back to its last position after power interruption. This function helps to recover embroidery after a power failure.

Supports Multiple Design Formats

The KX-Series embroidery machines support multiple design file formats to help maximise your production capabilities

Brand & Series:

SWF/KX-UH

Machine Speed (max)

1200spm (Tubular/Flat) (8 head:1100spm)

1000spm (QC Caps) (8 head:900spm)

Sewing Field:

Flat: 450mm x 400mm

Tubular: 319mm x 439mm

Quick Change (QC) Cap: 360 x 68 mm

Machine Size

Depth 794mm (delivery) / 1250mm (assembled with table)

Length (4 / 6 / 8 head) 2520mm / 3320mm / 4120mm

Height 1820mm

Included Frames:

2 each per head 9cm, 12cm, 15cm, and 18cm round hoops

2 each per head 32 x 44cm, 30 x 30cm square / rectangular hoops

2 each per head wide cap frames (270 degrees)

1 each per head quick change cap driver

Oil Lubrication:

One pull with Oil Reservoir

Machine Control:

Colour LCD Touch Screen Interactive 15.1” LCD touch screen

Machine Memory Capacity:

40 million stitch memory, up to 400 designs

Motors:

Main: Servo

X – Y: Servo

Power Consumption:

(2/4/6/8 head) 420W/475W/520W/725W

Memory Media:

2 x USB Ports

Oil Lubrication System:

Semi-Automatic Lubrication System

WiFi / Networking:

Connect up to 200 machines

Brand & Series:

SWF/KS-UK

Machine Speed (max)

1200spm (Tubular/Flat)

1000spm (QC Caps)

Machine Size

Depth 794mm (delivery) / 1250mm (assembled)

Length (2 / 4 / 6 head) 2020mm / 3046mm / 4046mm

Height 1820mm

Sewing Field:

Flat: 500mm x 450mm

Tubular: 450mm x 439mm

Quick Change (QC) Cap: 360 x 68 mm

Included Frames:

2 each per head 9cm, 12cm, 15cm, and 18cm round hoops

2 each per head 45 x 44cm, 30 x 30cm square / rectangular hoops

2 each per head wide cap frames (270 degrees)

1 each per head quick change cap driver

One pull with Oil Reservoir

Machine Control:

Colour LCD Touch Screen Interactive 15.1” LCD touch screen

Machine Memory Capacity:

40 million stitch memory, up to 400 designs

Motors:

Main: Servo

X – Y: Servo

Power Consumption:

(2/4/6/8 head) 420W/475W/520W/725W

Memory Media:

2 x USB Ports

Oil Lubrication System:

Semi-Automatic Lubrication System

WiFi / Networking:

Connect up to 200 machines