Using Triton HTV

Triton Heat Transfer Vinyl is a premium line of heat transfer vinyl offered in standard, opaque, glitter, and neon colors. This vinyl is well known

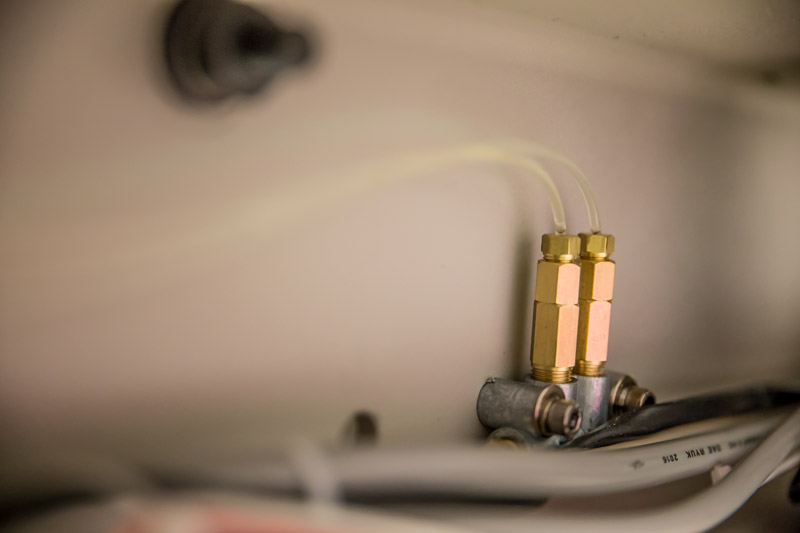

Getting the correct amount of oil in to each specific oiling point on any large mutli-head embroidery machine is crucial to ensure that precision moving parts are oiled correctly for smooth running.

Without oil, there is the potential for these precision parts to seize, resulting in machine down time and costly repairs. Getting the correct amount of oil in to each specific oiling point can also be a challenge – oiling needle bars alone can account for 120 oiling points on an eight head embroidery machine. Add to that the tubular arms (another 24 points), rotary hooks, linear guide rails, fixed heads – and so on. To complicate it further, each point may require a different quantity and / or frequency of oil. Apart from being very time consuming, there’s the potential of being distracted during the process and missing and / or over-oiling points.

SWF have solved this with their semi-automatic oiling system standard on the K, KE, KS and KX series of their tubular multi-head embroidery machines. All that’s required is for the operator to pump the handle of the oil reservoir and the system then automatically delivers the correct quantity of oil to ALL of those hard to get to, easy to otherwise forget, oiling points. Yes, the rotary hooks may require additional (manual) oiling during peak operation.

The oil tank is positioned at the front of the machine in an easy to see and easy to access location. Lubrication training of a new employee can be completed in minutes. No more forgotten oiling points, incorrect frequencies or incorrect quantities of oil.

Triton Heat Transfer Vinyl is a premium line of heat transfer vinyl offered in standard, opaque, glitter, and neon colors. This vinyl is well known

How do I know what sewing field size my machine is? We need measurements of your existing hoops so that we can